Other properties of Sintered Alnico and Cast Alnico Magnet

- Good temperature stability, suitable for use in high temperature environments

- Maximum operating temperature up to 525-550 ℃ (975-1020℉ )

- Can be polished to the required dimensional tolerances

- Magnet material is hard and brittle

- Higher residual induction and magnetic energy product than ceramic bonded magnets

- Resistance to demagnetization

sensors、motors、 microphones、electron tubes、relays、magnetic

reed switches、traveling wave tubes、 controls、loudspeakers、

radar、generators、hand tools、holding magnets、receivers、

educational products.

- Maximum operating temperature up to 525-550 ℃ (975-1020℉ )

- Can be polished to the required dimensional tolerances

- Magnet material is hard and brittle

- Higher residual induction and magnetic energy product than ceramic bonded magnets

- Resistance to demagnetization

MATERIAL CHARACTERISTICS

Magnetic Characteristics of Cast AlNiCo |

||||||||||||

Grade |

Residual Induction Br |

Coercive Force Hcj |

Max. Energy Product (BH)max |

Density D |

Temperature Coefficient % Change per℃ |

Curie Temperature Tc |

Working Temperature Tw |

Equivalent MMPA Class |

||||

mT |

Gs |

kA/m |

Oe |

kJ/m3 |

MGOe |

g/cm3 |

NearBr |

Near Hcj |

℃ |

℃ |

||

LN9 |

680 |

6800 |

30 |

380 |

9 |

1.13 |

6.9 |

-0.03 |

-0.02 |

810 |

450 |

AlNiCo3 |

LN10 |

600 |

6000 |

40 |

500 |

10 |

1.2 |

6.9 |

-0.03 |

-0.02 |

810 |

450 |

|

LNG12 |

720 |

7200 |

45 |

500 |

12.4 |

1.55 |

7 |

-0.03 |

-0.02 |

810 |

450 |

AlNiCo2 |

LNG13 |

700 |

7000 |

48 |

600 |

12.8 |

1.6 |

7 |

-0.03 |

-0.02 |

810 |

450 |

|

LNG37 |

1200 |

12000 |

48 |

600 |

37 |

4.65 |

7.3 |

-0.02 |

-0.02 |

860 |

525 |

AlNiCo5 |

LNG40 |

1250 |

12500 |

48 |

600 |

40 |

5 |

7.3 |

-0.02 |

-0.02 |

860 |

525 |

|

LNG44 |

1250 |

12500 |

52 |

650 |

44 |

5.5 |

7.3 |

-0.02 |

-0.02 |

860 |

525 |

|

LNG52 |

1300 |

13000 |

56 |

700 |

52 |

6.5 |

7.3 |

-0.02 |

-0.02 |

860 |

525 |

AlNiCo5D |

LNG60 |

1350 |

13500 |

59 |

740 |

60 |

7.5 |

7.3 |

-0.02 |

-0.02 |

860 |

525 |

AlNiCo5-7 |

LNGT28 |

1000 |

10000 |

58 |

720 |

28 |

3.5 |

7.3 |

-0.02 |

-0.03 |

860 |

525 |

AlNiCo6 |

LNGT36J |

700 |

7000 |

140 |

1750 |

36 |

4.5 |

7.3 |

-0.025 |

-0.02 |

860 |

550 |

AlNiCo8H |

LNGT18 |

580 |

5800 |

100 |

1250 |

18 |

2.2 |

7.3 |

-0.025 |

-0.02 |

860 |

550 |

AlNiCo8 |

LNGT32 |

800 |

8000 |

100 |

1250 |

32 |

4 |

7.3 |

-0.025 |

-0.02 |

860 |

550 |

AlNiCo8 |

LNGT40 |

800 |

8000 |

110 |

1380 |

40 |

5 |

7.3 |

-0.025 |

-0.02 |

860 |

550 |

|

LNGT60 |

900 |

9000 |

110 |

1380 |

60 |

7.5 |

7.3 |

-0.025 |

-0.02 |

860 |

550 |

AlNiCo9 |

LNGT72 |

1050 |

10500 |

112 |

1400 |

72 |

9 |

7.3 |

-0.025 |

-0.02 |

860 |

550 |

|

Magnetic Characteristics of sintered AlNiCo |

||||||||||||

Grade |

Residual Induction Br |

Intrinsic Coercive Force Hcj |

Coercive Force Hcb |

Max. Energy Product (BH)max |

Curie Temperature Tc |

Temperature Coefficient % Change per℃ |

Density D |

Remark |

||||

mT |

Gs |

kA/m |

Oe |

kA/m |

Oe |

kJ/m3 |

MGOe |

℃ |

%/℃ |

g/cm3 |

||

FLN8 |

520 |

5200 |

43 |

540 |

40 |

500 |

8-10 |

1.0-1.25 |

760 |

-0.022 |

6.8 |

Isotropic |

FLNG12 |

700 |

7000 |

43 |

540 |

40 |

500 |

12-14 |

1.5-1.75 |

810 |

-0.014 |

7 |

|

FLNGT14 |

570 |

5700 |

78 |

980 |

76 |

950 |

14-16 |

1.75-2.0 |

850 |

-0.02 |

7.1 |

|

FLNGT18 |

560 |

5600 |

90 |

1130 |

88 |

1100 |

18-22 |

2.25-2.75 |

850 |

-0.02 |

7.2 |

|

FLNG28 |

1050 |

10500 |

47 |

590 |

46 |

580 |

28-33 |

3.5-4.15 |

850 |

-0.016 |

7.2 |

Anisotropic |

FLNG34 |

1100 |

11000 |

51 |

640 |

50 |

630 |

34-38 |

4.3-4.8 |

890 |

-0.016 |

7.2 |

|

FLNGT28 |

1000 |

10000 |

57 |

710 |

56 |

700 |

28-30 |

3.5-3.8 |

850 |

-0.02 |

7.2 |

|

FLNGT31 |

780 |

7800 |

106 |

1130 |

104 |

1300 |

33-36 |

3.9-4.5 |

850 |

-0.02 |

7.2 |

|

FLNG33J |

650 |

6500 |

150 |

1880 |

136 |

1700 |

31-36 |

4.15-4.5 |

850 |

-0.02 |

7.2 |

|

FLNGT38 |

800 |

8000 |

126 |

1580 |

123 |

1550 |

38-42 |

4.75-5.3 |

850 |

-0.02 |

7.2 |

|

FLNGT42 |

880 |

8800 |

122 |

1530 |

120 |

1500 |

42-48 |

5.3-6.0 |

850 |

-0.02 |

7.25 |

|

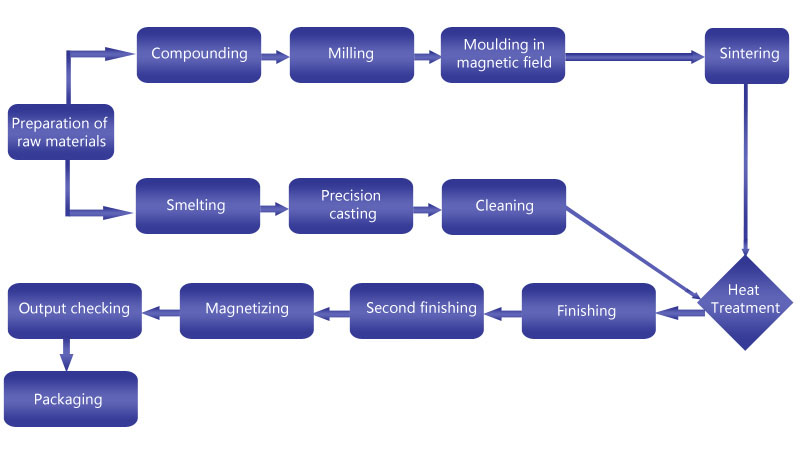

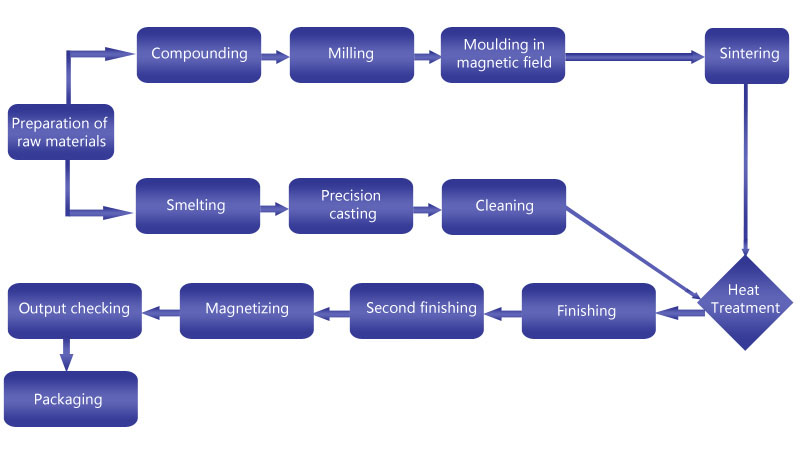

Production Process Flowchart

PRODUCT ADVANTAGE

QUALITY

Applications

Mainly used for water meter、clutches and bearings、telephones、sensors、motors、 microphones、electron tubes、relays、magnetic

reed switches、traveling wave tubes、 controls、loudspeakers、

radar、generators、hand tools、holding magnets、receivers、

educational products.