Material Characteristics

Material Characteristics of CPE SeriesGrade |

Residual Induction Br |

Coercive Force Hcb |

Intrinsic Coercive Force Hcj |

Max. Energy Product (BH)max |

Material |

Application |

JPM-R1A |

175~200mT |

107.5~151.3kA/m |

139.3~191.1kA/m |

6~8.5kJ/m3 |

SrO·6Fe2O3 MIX Rubber |

Stationery Toy Holder |

1700~2000Gs |

1350~1900Oe |

1750~2400Oe |

0.75~1.06MGOe |

|||

JPM-R1B |

165~195mT |

91.5~143.3kA/m |

123.4~175.2kA/m |

5~7.5kJ/m3 |

SrO·6Fe2O3 MIX Rubber |

|

1650~1950Gs |

1150~1800Oe |

1550~2200Oe |

0.63~0.94MGOe |

|||

JPM-R2A |

225~255mT |

139.4~171.2kA/m |

167.1~206.9kA/m |

10.18~11.78kJ/m3 |

SrO·6Fe2O3 MIX Rubber |

|

2250~2550Gs |

1750~2150Oe |

2100~2600Oe |

1.28~1.48MGOe |

|||

JPM-R2B |

225~255mT |

159.2~183.0kA/m |

199.0~246.0kA/m |

10.4~12.0kJ/m3 |

SrO·6Fe2O3 MIX Rubber |

Automotive Motors Micro-motor OA Facilities Stationery Toy Holder Household Appliance |

2250~2550Gs |

2000~2300Oe |

2500~3100Oe |

1.3~1.5MGOe |

|||

JPM-R2C |

230~260mT |

159.2~183.0kA/m |

191.0~230.7kA/m |

10.4~12.0kJ/m3 |

SrO·6Fe2O3 MIX Rubber |

|

2300~2600Gs |

2000~2300Oe |

2400~2900Oe |

1.3~1.5MGOe |

|||

JPM-R2E |

240~270mT |

167.2~191.0kA/m |

199.0~246.0kA/m |

11.2~12.8kJ/m3 |

SrO·6Fe2O3 MIX Rubber |

|

2400~2700Gs |

2100~2400Oe |

2500~3100Oe |

1.4~1.6MGOe |

|||

JPM-R2G |

220~260mT |

147.3~195.1kA/m |

163.2~206.9kA/m |

9.6~12.8kJ/m3 |

SrO·6Fe2O3 MIX Rubber |

|

2200~2600Gs |

1850~2450Oe |

2050~2600Oe |

1.20~1.60MGOe |

|||

JPM-R2H |

225~255mT |

155.2~191.1kA/m |

≥215kA/m |

10.0~11.6kJ/m3 |

SrO·6Fe2O3 MIX Rubber |

|

2250~2550Gs |

1950~2400Oe |

≥2700Oe |

1.25~1.45MGOe |

|||

JPM-R2I |

225~255mT |

135.4~175.2kA/m |

167.1~222.9kA/m |

9.55~12kJ/m3 |

SrO·6Fe2O3 MIX Rubber |

|

2250~2550Gs |

1700~2200Oe |

2100~2800Oe |

1.2~1.5MGOe |

|||

JPM-R2J |

240~270mT |

160.0~191.0kA/m |

183.1~214.9kA/m |

11.2~12.8kJ/m3 |

SrO·6Fe2O3 MIX Rubber |

|

2400~2700Gs |

2011~2400Oe |

2300~2700Oe |

1.4~1.6MGOe |

CPE Reliability Properties Test

Grade |

JPM-R1A |

JPM-R1B |

JPM-R2A |

JPM-R2B |

JPM-R2C |

JPM-R2D |

JPM-R2E |

JPM-R2F |

JPM-R2G |

JPM-R2H |

JPM-R2I |

Tensile Strength(Mpa) |

>2.5 |

>2.5 |

>2.5 |

>2.5 |

>2.5 |

>2.5 |

>2.5 |

>2.5 |

>2.5 |

>2.5 |

>2.5 |

Elongation(%) |

>20 |

>20 |

>20 |

>20 |

>20 |

>20 |

>20 |

>20 |

>20 |

>20 |

>20 |

Hardness(shore D) |

40~65 |

40~65 |

40~65 |

40~65 |

40~65 |

40~65 |

40~65 |

40~65 |

40~65 |

40~65 |

40~65 |

Weight Reduction By Heat(%) |

<2.0 |

<2.0 |

<2.0 |

<2.0 |

<2.0 |

<2.0 |

<2.0 |

<2.0 |

<2.0 |

<2.0 |

<2.0 |

Density (g/cm3) |

3.6~3.8 |

3.6~3.8 |

3.6~3.8 |

3.6~3.8 |

3.6~3.8 |

3.6~3.8 |

3.6~3.8 |

3.6~3.8 |

3.6~3.8 |

3.6~3.8 |

3.6~3.8 |

Operation Temperature(℃) |

-40~80 |

-40~80 |

-40~80 |

-40~80 |

-40~80 |

-40~80 |

-40~80 |

-40~80 |

-40~80 |

-40~80 |

-40~80 |

Reversing Temperature(%/℃ ) |

-0.18 |

-0.18 |

-0.18 |

-0.18 |

-0.18 |

-0.18 |

-0.18 |

-0.18 |

-0.18 |

-0.18 |

-0.18 |

Motor Oil(23℃×72h) |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

Alcohol(23℃×72h) |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

Weak Alkali(23℃×72h) |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

Detergent(23℃×72h) |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

30%Benzene+ 70%Gasoline(23℃×72h) |

× |

× |

× |

× |

× |

× |

× |

× |

× |

× |

× |

Organic, Inorganic Acid(23℃×72h) |

× |

× |

× |

× |

× |

× |

× |

× |

× |

× |

× |

Aether,Ketone ,Thinner(23℃×72h) |

× |

× |

× |

× |

× |

× |

× |

× |

× |

× |

× |

Water(60℃×72h) |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

Burn-resistant |

V0 |

V0 |

V0 |

V0 |

V0 |

V0 |

V0 |

V0 |

V0 |

V0 |

V0 |

Heat-resistant(80℃×72h) |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

Cold-resistant(-40℃×72h) |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

Wet-resistant (60℃×90%RH×72h) |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

Heat-impact (-40℃~80℃×0.5h×25Cycle) |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

Remark: ***Excellent **Good *Fair ×Bad

Material Characteristics of NBR Series

Grade |

Residual Induction Br |

Coercive Force Hcb |

Intrinsic Coercive Force Hcj |

Max. Energy Product (BH)max. |

Material |

Application |

JPM-R3A |

240 ~ 270mT |

167 ~ 199kA/m |

210.7~266.7kA/m |

11.2~12.8kJ/m3 |

SrO·6Fe2O3 MIX NBR |

Automotive Motors Micro-motor Household Appliance OA Facilities Stationery/Toy Holder |

2400 ~ 2700Gs |

2100 ~ 2500Oe |

2650 ~ 3350Oe |

1.4~1.6MGOe |

|||

JPM-R3AL |

215 ~ 250mT |

143.1~ 175.1kA/m |

175.1~222.8kA/m |

9.5~11.2kJ/m3 |

SrO·6Fe2O3 MIX NBR |

|

2150~ 2500Gs |

1800 ~ 2200Oe |

2200 ~ 2800Oe |

1.2~1.4MGOe |

|||

JPM-R3B |

230 ~ 260mT |

163 ~ 195kA/m |

234.5~290.5kA/m |

11.2~12.8kJ/m3 |

SrO·6Fe2O3 MIX NBR |

|

2300 ~ 2600Gs |

2050 ~ 2450Oe |

2950~3650MGOe |

1.4~1.6MGOe |

|||

JPM-R3C |

225 ~ 255mT |

171 ~ 203kA/m |

258.4~314.4kA/m |

11.2~12.8kJ/m3 |

SrO·6Fe2O3 MIX NBR |

|

2250 ~ 2550Gs |

2150 ~ 2550Oe |

3250~3950MGOe |

1.4~1.6MGOe |

Material Characteristics

Grade |

Residual Induction Br |

Coercive Force Hcb |

Intrinsic Coercive Force Hcj |

Max. Energy Product (BH)max. |

Material |

Application |

JPM-RN1 |

260 ~ 280mT |

183~ 199kA/m |

239~358kA/m |

12.7~15.9kJ/m3 |

NdFeB MIX Rubber |

Automotive Motors Micro-motor Household Appliance OA Facilities Stationery Toy Holder |

2600 ~ 2800Gs |

2300 ~ 2500Oe |

3000~4500Oe |

1.6~2.0MGOe |

|||

JPM-RN2 |

280 ~ 350mT |

199 ~ 279kA/m |

358~518kA/m |

15.9~22.3kJ/m3 |

NdFeB MIX Rubber |

|

2800 ~ 3500Gs |

2500 ~ 3500Oe |

4500~6500Oe |

2.0~2.8MGOe |

|||

JPM-RN3 |

350 ~ 400mT |

239 ~ 279kA/m |

478~597kA/m |

22.3~27.9kJ/m3 |

NdFeB MIX Rubber |

|

3500 ~ 4000Gs |

3000 ~ 3500Oe |

6000~7500Oe |

2.8~3.5MGOe |

|||

JPM-RN4 |

400 ~ 460mT |

263~ 318kA/m |

557~677kA/m |

27.9~35.8kJ/m3 |

NdFeB MIX Rubber |

|

4000 ~ 4600Gs |

3300 ~ 4000Oe |

7000~8500Oe |

3.5~4.5MGOe |

|||

JPM-RN5 |

460 ~ 500mT |

295 ~ 334kA/m |

637~740kA/m |

35.8~42.2kJ/m3 |

NdFeB MIX Rubber |

|

4600 ~ 5000Gs |

3700 ~ 4200Oe |

8000~9300Oe |

4.5~5.3MGOe |

|||

JPM-RN6 |

500 ~ 550mT |

311 ~ 350kA/m |

677~756kA/m |

42.2~49.4kJ/m3 |

NdFeB MIX Rubber |

|

5000 ~ 5500Gs |

3900 ~ 4400Oe |

8500~9500Oe |

5.3~6.2MGOe |

Physical Characteristics

Grade |

Tensile Strength (Mpa) |

Elongation (%) |

Hardness (SHORE D) |

Temperature (℃) |

Density (g/cm3) |

JPM-RN1 |

9 ~15 |

50 ~85 |

30 ~50 |

-10 ~60 |

3.70~5.50 |

JPM-RN2 |

8 ~12 |

50 ~85 |

30~50 |

-10 ~60 |

3.70 ~5.50 |

JPM-RN3 |

6 ~10 |

40 ~70 |

30~50 |

-10 ~60 |

3.70~5.50 |

JPM-RN4 |

5 ~8 |

30 ~50 |

25 ~45 |

-10 ~60 |

3.70 ~5.50 |

JPM-RN5 |

2 ~6 |

15 ~40 |

25 ~45 |

-10 ~50 |

3.70 ~5.50 |

JPM-RN6 |

2 ~6 |

15~40 |

25 ~45 |

-10 ~50 |

3.70 ~5.50 |

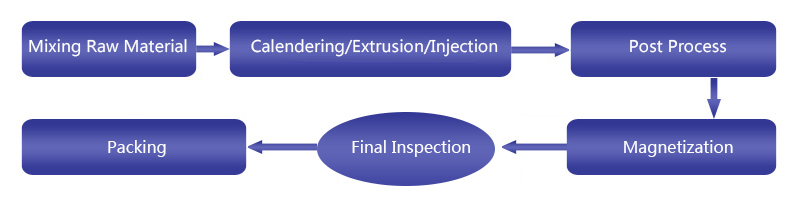

Production Process Flowchart

PRODUCT ADVANTAGE

QUALITY

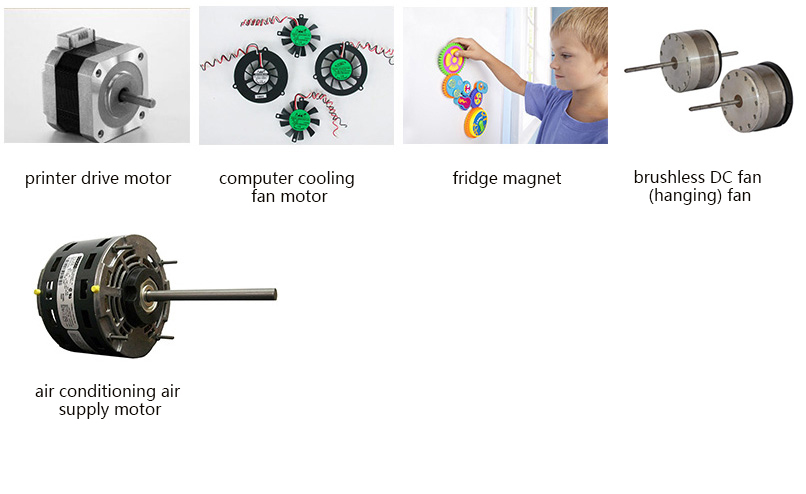

Applications

Products are mainly used for: computer cooling fan motor, air conditioning air supply motor,printer drive motor, VCD and DVD drive motor, brushless DC fan (hanging) fan, children's

toys, office stationery, household goods, magnetic door seal, Healthy magnetic mattress sticks。