Type

Mn-Zn Soft Ferrite Cores

Mn-Zn ferrite core is consist of a combination of iron oxide and strontium carbonate. Thanks to their low cost, light weight, relatively high energy products and good anti-demagnetization , ferrite and ceramic magnets are widely used. The ferrite and ceramic magnets (Mn-Zn ferrite cores) have a maximum operating temperature of 480 ° F, which is ideal for some high temperature applications.

Common applications include: loudspeaker magnets, motors, metallic reed switches and hall effect devices.

Ni-Zn Soft Ferrite Cores

Ferrite wideband devices, which is made by Nickel-Zinc magnetic ring. The use of frequency can be very wide, the lower limit frequency can be done several kilohertz, the upper limit frequency up to several gigahertz, expanded the soft magnetic material frequency greatly. The main function is to realize the energy transmission and impedance conversion of the RF signal in the wide frequency range. Because of their frequency bandwidth, small size, light weight and other characteristics, they can be widely used in radar, television, communications, instrumentation, automatic control, electronic warfare and other fields.

Material Characteristics of MnZn Power Ferrite

Grade |

Initial Permeability μi

|

Saturation Flux Density BS(mT) 1194 A/m |

Core Loss Pcv(kW/m3) 100kHz、200mT

|

Curie Temperature (℃) |

Density ( kg/m3) |

|||||||

25℃ |

100℃ |

140℃ |

25℃ |

60℃ |

100℃ |

120℃ |

140℃ |

|||||

CYP–4 |

2400±25% |

500 |

390 |

- |

600 |

460 |

410 |

- |

- |

>215 |

4.8x103 |

|

CYP–4T (new) |

1800±25% |

520 |

430 |

360 |

900 |

- |

500 |

- |

400 |

>240 |

4.8x103 |

|

CYP–44 |

2400±25% |

510 |

390 |

- |

600 |

400 |

300 |

380 |

- |

>215 |

4.8x103 |

|

CYP–44A |

2400±25% |

530 |

410 |

- |

600 |

400 |

280 |

380 |

- |

>215 |

4.8x103 |

|

CYP–44C |

2400±25% |

530 |

420 |

- |

550 |

380 |

250 |

360 |

- |

>215 |

4.8x103 |

|

CYP–44B |

2400±25% |

510 |

390 |

- |

300Ⅰ 550Ⅱ |

- |

150Ⅰ 350Ⅱ |

- |

- |

>215 |

4.8x103 |

|

CYP–5A |

1400±25% |

490 |

390 |

- |

130Ⅲ 160Ⅳ |

80Ⅲ 130Ⅳ |

80Ⅲ 130Ⅳ |

110Ⅲ 160Ⅳ |

- |

>250 |

4.7x103 |

|

CYB–60 (new) |

1000±25% |

580 |

490 |

- |

1200 |

- |

650 |

- |

- |

>300 |

4.9x103 |

|

CYP–90 |

2200±25% |

540 |

450 |

- |

680 |

- |

320 |

- |

- |

>250 |

4.9x103 |

|

CYP–95 |

3300±25% |

530 |

410 |

- |

350 |

290 |

300 |

360 |

- |

>215 |

4.8x103 |

|

CYP–95A |

3300±25% |

530 |

410 |

- |

330 |

280 |

290 |

350 |

- |

>215 |

4.8x103 |

|

CYP–95B |

3300±25% |

530 |

410 |

- |

310 |

280 |

290 |

340 |

- |

>215 |

4.8x103 |

|

CYP–96 |

3000±25% |

540 |

450 |

- |

360 |

310 |

300 |

350 |

- |

>250 |

4.9x103 |

|

CYP–97 |

3000±25% |

530 |

410 |

- |

380 |

320 |

300 |

320 |

380 |

>215 |

4.8x103 |

|

Ⅰ Test Conditions:200kHz、100mT; ⅡTest Conditions:300kHz、100mT;

Ⅲ Test Conditions:500kHz、50mT; ⅣTest Conditions:1MHz、30mT。

MnZn High Permeability/High Impedance Ferrite Material Characteristics

Grade |

Initial Permeability

μi |

Saturation Flux Density Bs(mT) |

Relative Loss Factor tanδ/μi |

Electric Resistivity ρ Ω·m |

Curie Temperature (℃) |

Density ( kg/m3) |

|

25℃、1194 A/m |

x10-6(10kHz) |

||||||

CYH–5 |

5000±25% |

450 |

3.5 |

0.5 |

>135 |

4.8x103 |

|

CYH–5T (new) |

5500±25% |

460 |

2.5 |

0.5 |

>160 |

4.85x103 |

|

CYH–7F |

7000±25% |

430 |

6.5 |

0.15 |

>125 |

4.9x103 |

|

CYH–10F |

10000±30% |

420 |

1.6 |

0.3 |

>120 |

5.0x103 |

|

CYH–12F |

12000±30% |

400 |

1.6 |

0.3 |

>110 |

5.0x103 |

|

CYH–15F (new) |

15000±30% |

400 |

1.6 |

0.3 |

>105 |

5.0x103 |

|

CYB–45 |

4200±25% |

470 |

3 |

2 |

>160 |

4.85x103 |

|

Material Characteristics of Ni-Zn Soft Ferrite Cores

Grade |

Initial Permeability μi |

Relative Temperature Factor αuir |

Relative Loss Factor tanδ/μi |

Saturation Flux Density Bs |

Curie Temperature Tc |

Electric Resistivity ρ |

Density d |

Material |

±25% |

X10-6/℃ (20℃-60℃) |

X10-6 (MHz) |

mT |

℃ |

Ω·m |

g/cm3 |

CYL60 |

60 |

40 |

<200(10M) |

300 |

300 |

106 |

5.0 |

CYL2H |

200 |

35 |

<100(0.1M) |

390 |

230 |

106 |

5.0 |

CYL3H |

300 |

30 |

<30(0.1M) |

410 |

200 |

106 |

5.0 |

CYL5H |

500 |

20 |

<40(0.1M) |

380 |

200 |

106 |

5.0 |

CYT5H |

500 |

15 |

<60(0.1M) |

400 |

200 |

106 |

5.0 |

CYL6H |

600 |

10 |

<80(0.1M) |

370 |

180 |

106 |

5.0 |

CYT7H |

700 |

8 |

<100(0.1M) |

390 |

180 |

106 |

5.0 |

CYL8H |

800 |

4 |

<200(0.1M) |

350 |

160 |

106 |

5.0 |

CYL9H |

900 |

3 |

<100(0.1M) |

320 |

120 |

106 |

5.0 |

CYZ3H |

300 |

40 |

<600(0.1M) |

230 |

150 |

106 |

4.7 |

CYZ4H |

400 |

15 |

<500(0.1M) |

240 |

140 |

106 |

4.7 |

CYZ1K |

800 |

15 |

<100(0.1M) |

260 |

110 |

106 |

4.8 |

CYZ1.2K |

1200 |

35 |

<130(0.1M) |

230 |

100 |

106 |

4.8 |

CYZ1.5K |

1500 |

10 |

<100(0.1M) |

260 |

100 |

106 |

5.0 |

CYL2K |

2000 |

30 |

<80(0.5M) |

250 |

100 |

106 |

5.0 |

1. Typical values

2. This values were obtained with toroidal cores(OD25 x H8 x ID15) at 23℃ unless otherwise shown.

3. For improvement of its products, Magsource reserves the right to change specifications without prior notice to customers.

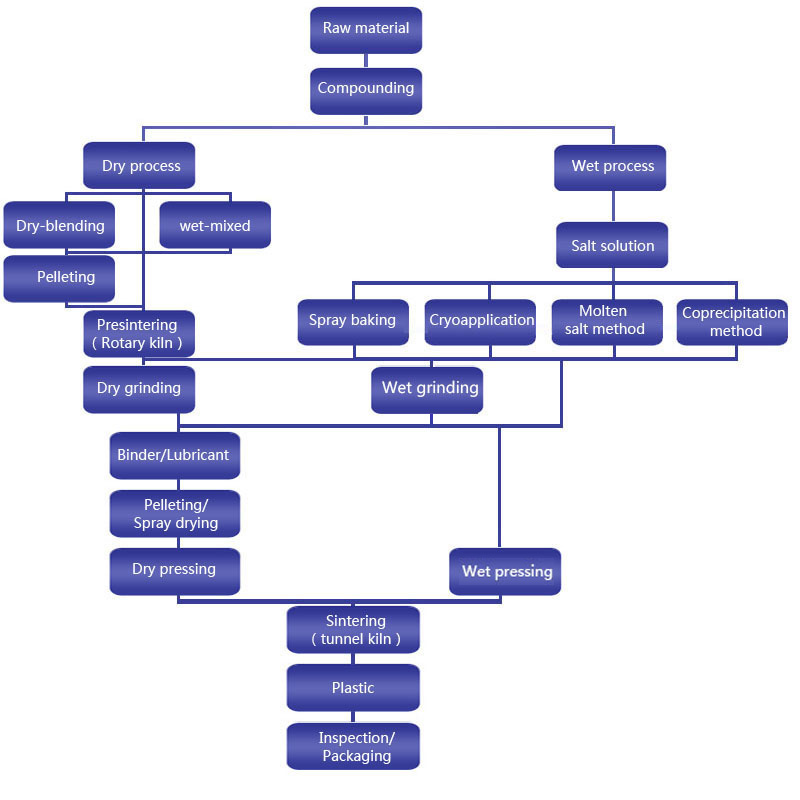

Production Process Flowchart

PRODUCT ADVANTAGE

QUALITY

APPLICATIONS

Mn-Zn Soft Ferrite CoresProductions are mainly used in: switching power supply, telecommunication, household appliances, anti-electromagnetic interference (EMI) etc.

Ni-Zn Soft Ferrite Cores

Products are mainly used in: modern telecommunication, computer and peripheral equipment, office facilities, household appliances, automotive and anti-electromagnetic interference etc.